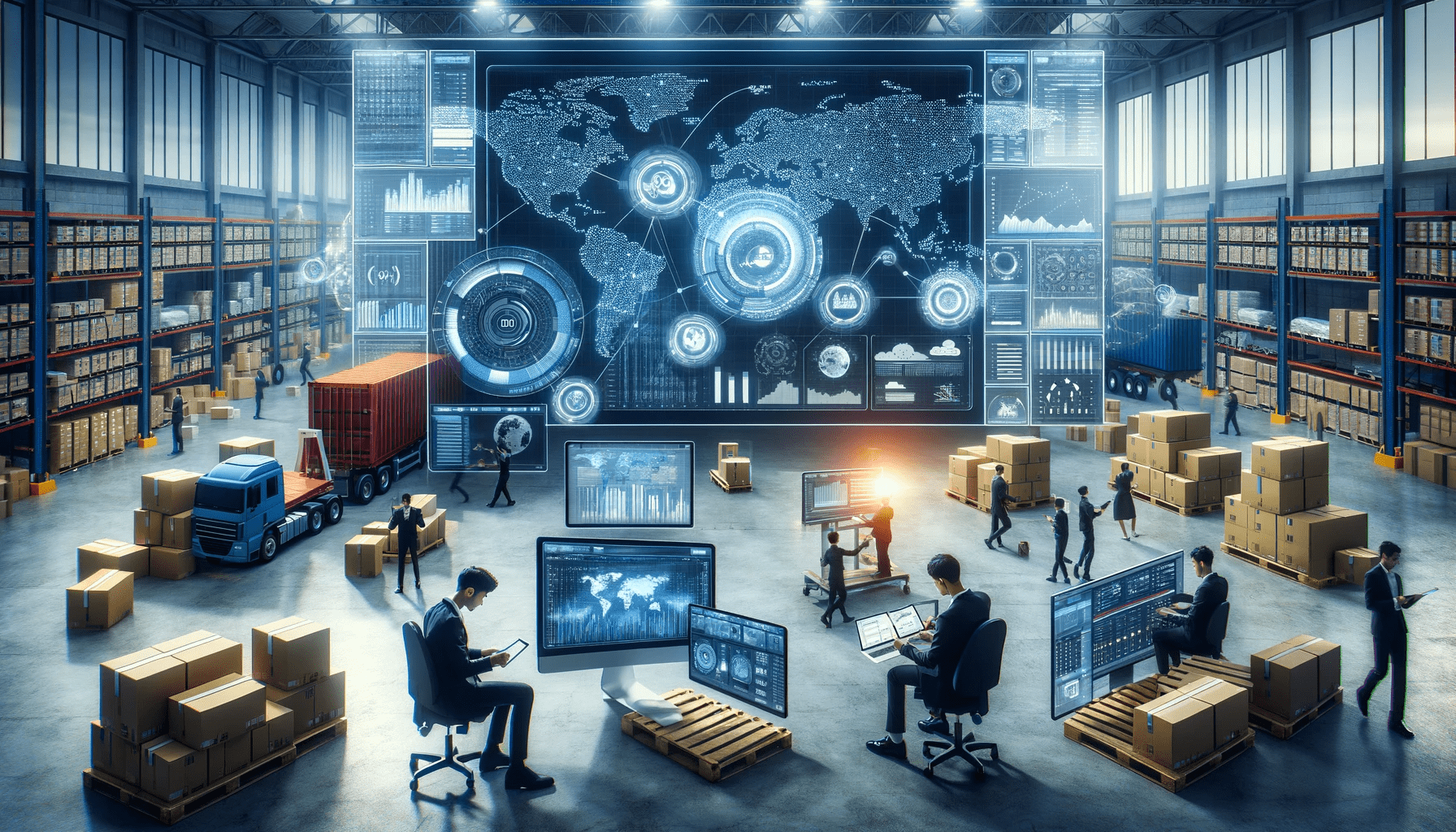

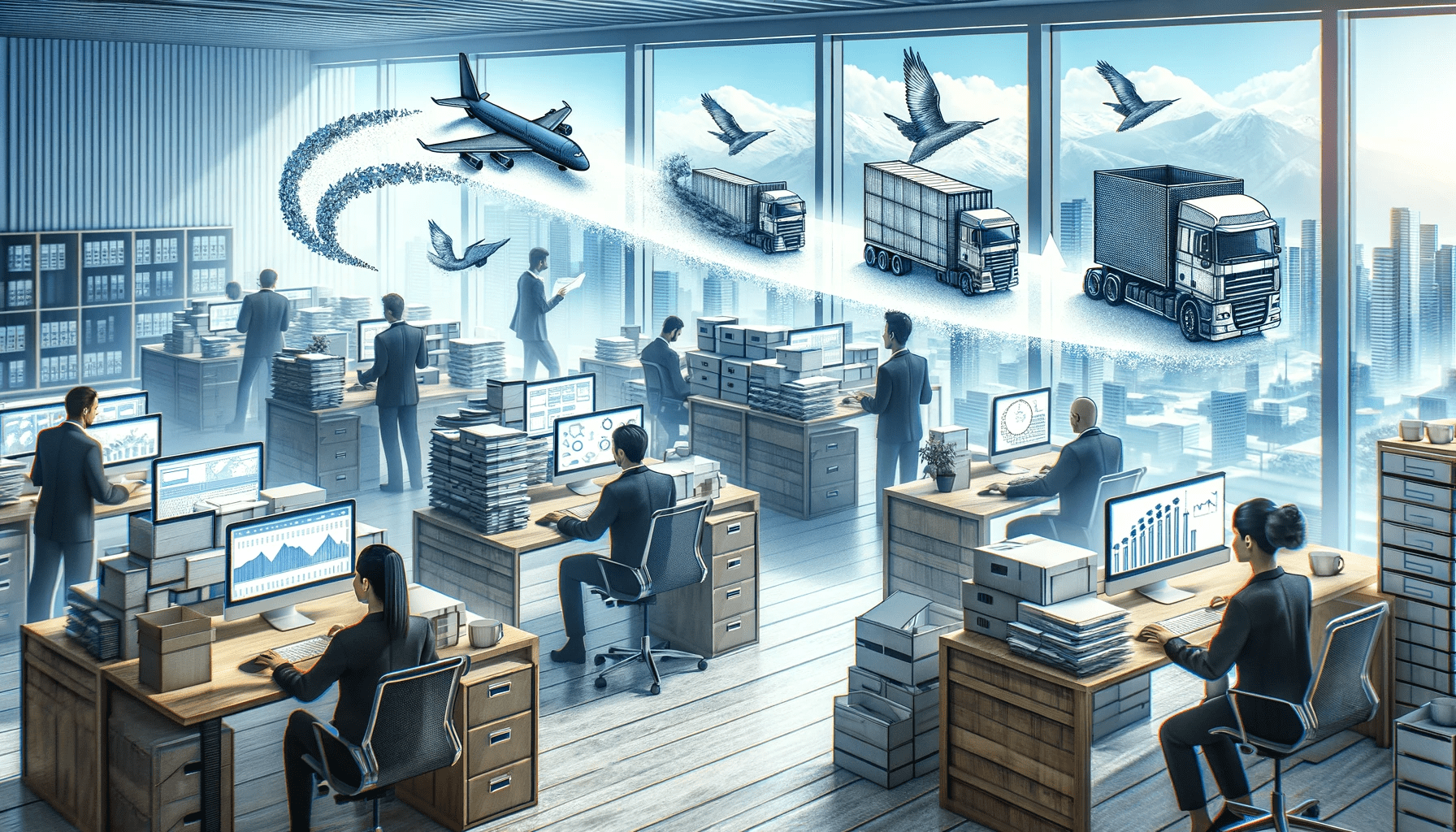

The Role of Data Analytics

A critical component of this digital shift is data analytics. By harnessing the power of data, companies can gain valuable insights into every aspect of their supply chain. This includes understanding buying patterns, predicting market trends, optimising inventory levels, and identifying potential bottlenecks before they become critical issues.

For example, predictive analytics can be used to forecast demand more accurately, ensuring that stock levels are optimised to meet customer needs without tying up too much capital in inventory. Similarly, data analytics can provide real-time insights into logistics, allowing companies to track shipments in real time and anticipate delays.

Integrated Digital Platforms

Another key aspect of digital transformation is the integration of various supply chain functions into a unified digital platform. This integration allows for seamless communication and data exchange between different departments and external partners. Such platforms not only improve operational efficiency but also enhance transparency and collaboration across the supply chain.

For instance, an integrated platform can enable a distributor to automatically update inventory levels, process orders more quickly, and provide customers with real-time updates on their order status. This level of efficiency and customer service can be a significant differentiator in the competitive world of wholesale import distribution.

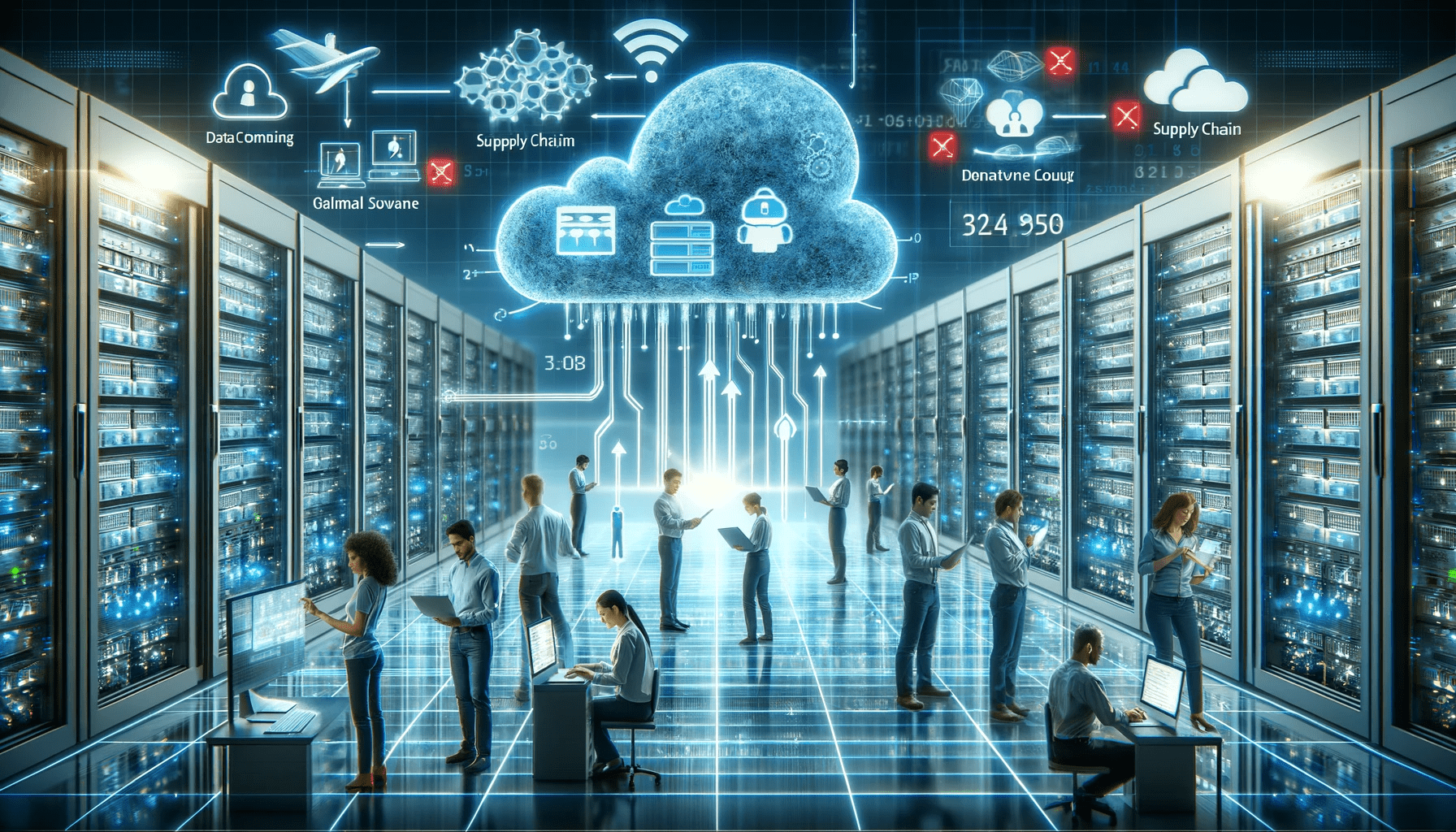

Leveraging Cloud Computing for Scalability and Flexibility in Your Supply Chain

In the intricate world of wholesale import distribution, scalability and flexibility are key to adapting to market changes and customer demands. Cloud computing emerges as a pivotal solution, offering a dynamic and efficient approach to supply chain management.

Scalability to Meet Market Demands

One of the primary advantages of cloud-based solutions is their inherent scalability. As the needs of your business grow, cloud computing can effortlessly scale up to accommodate increased data processing, more extensive inventory management, or a higher volume of orders. This elasticity is essential for import distribution companies that experience seasonal spikes or are on a growth trajectory.

For instance, during peak seasons, when the volume of orders surges, cloud platforms can manage this increased workload without the need for significant infrastructure changes. This flexibility ensures that businesses can respond to market demands quickly and efficiently.

Enhanced Flexibility and Integration

Cloud computing also offers unparalleled flexibility. It allows for seamless integration of various supply chain components – from warehousing and logistics to customer relationship management and data analytics. By hosting these elements in the cloud, businesses can ensure real-time data synchronisation and access from any location, fostering better decision-making and more responsive supply chain management.

Moreover, cloud solutions facilitate integration with other technologies such as IoT for real-time tracking or AI for predictive analytics, further enhancing the efficiency of the supply chain.

Cost-Effective and Secure Operations

Adopting cloud computing can also be more cost-effective than traditional IT infrastructure. With cloud services, businesses typically pay for what they use, avoiding the capital expense of maintaining physical servers. Additionally, cloud service providers offer robust security measures, which is crucial for protecting sensitive supply chain data.

The Importance of Cybersecurity in Protecting the Supply Chain

In the digital era, where supply chains are increasingly interconnected and reliant on technology, cybersecurity has become a critical pillar of operation. For wholesale import distribution companies, where the flow of goods is matched by the flow of data, the need to protect this data is paramount. Cyber threats can disrupt operations, lead to financial loss, and damage a company’s reputation.

Rising Threats in a Connected World

The sophistication and frequency of cyber attacks have risen dramatically. One notable example was the Maersk cyber attack in 2017, where the company suffered a massive breach due to the NotPetya ransomware, leading to an estimated $300 million in damages. This incident highlights how a single vulnerability can have cascading effects throughout the entire supply chain.

Protecting Data Across the Supply Chain

Cybersecurity in supply chain management isn’t just about protecting internal data; it’s also about safeguarding information shared with and received from suppliers, logistics partners, and customers. For instance, a breach in a supplier’s system can compromise the security of the entire network. Implementing standardised security protocols across the supply chain is, therefore, essential.

Mitigation Strategies

To protect against cyber threats, companies should adopt a multi-layered security approach. This includes:

- Regular Risk Assessments: Continuously identifying and assessing potential vulnerabilities in the supply chain.

- Employee Training and Awareness: Ensuring that all employees are trained in basic cybersecurity practices, as human error often leads to breaches.

- Robust IT Infrastructure: Implementing advanced security solutions like firewalls, anti-virus programs, and intrusion detection systems.

- Data Encryption: Encrypting sensitive data, both in transit and at rest, adds an additional layer of security.

- Regular Software Updates: Keeping all systems and software updated to protect against the latest threats.

- Business Continuity Planning: Having a robust plan in place for how to respond to and recover from a cyber attack.

Real-Life Implications

An example underscoring the importance of robust cybersecurity measures was the attack on Toll Group in 2020. This logistics giant faced two ransomware attacks within the span of three months, severely disrupting their operations and causing delays in shipments and deliveries.

Utilising IoT and Smart Technologies for Real-Time Tracking and Efficiency

The integration of the Internet of Things (IoT) and smart technologies in the supply chain represents a significant advancement in the way wholesale import distribution companies manage and track their inventory and shipments. By harnessing these technologies, businesses can gain real-time insights, improve efficiency, and significantly reduce operational costs.

Real-Time Tracking for Enhanced Visibility

One of the most notable applications of IoT in the supply chain is in real-time tracking of shipments. GPS-enabled IoT devices can be attached to shipping containers or individual products, providing continuous location tracking. This level of visibility is crucial for timely deliveries, especially in a scenario where delays can lead to significant losses.

For example, a New Zealand-based wine distributor using IoT sensors can monitor the location and condition (like temperature and humidity) of their shipments in real-time, ensuring the quality of their product upon arrival.

IoT for Inventory Management

IoT technologies also revolutionise inventory management. Smart shelves equipped with weight sensors and RFID tags can automatically track stock levels, sending alerts when it’s time to reorder. This automation reduces the likelihood of overstocking or stockouts, optimising inventory levels based on actual demand.

Consider a scenario where an importer of automotive parts uses IoT-enabled warehouses. Sensors on the shelves detect when specific parts are running low and automatically trigger a procurement request. This streamlined process ensures that the most in-demand parts are always available, improving customer satisfaction and operational efficiency.

Predictive Maintenance and Efficiency

Additionally, IoT can be used for predictive maintenance of equipment in warehouses and distribution centres. Sensors can detect when a machine is likely to fail, allowing for maintenance before a breakdown occurs, thereby minimising downtime.

For instance, a distribution center could use vibration sensors on conveyor belts to predict and prevent failures, ensuring continuous operation and reducing unexpected delays.

Preparing for Future Challenges and Trends in Digital Supply Chain Management

As we venture deeper into the digital age, the landscape of supply chain management continues to evolve at a rapid pace. Wholesale import distribution companies must not only adapt to current trends but also anticipate future shifts to stay ahead. Here’s a look at upcoming trends and challenges, and strategies for maintaining a competitive edge.

Embracing Advanced Analytics and AI

The future of supply chain management is deeply intertwined with advancements in analytics and artificial intelligence (AI). These technologies offer predictive insights that can transform decision-making processes. For instance, AI-driven analytics can forecast market trends, consumer behaviour, and supply chain disruptions with greater accuracy, enabling companies to prepare and adjust their strategies proactively.

Integration of Blockchain Technology

Blockchain technology is poised to revolutionise supply chain transparency and security. By providing an immutable ledger of transactions and movements, blockchain can offer unparalleled traceability of products from manufacturer to consumer. This transparency is particularly crucial for importer distribution companies dealing with a multitude of international suppliers and regulations.

Sustainability and Ethical Supply Chains

As consumer awareness and regulatory pressures around sustainability grow, companies will face increasing demand for ethically sourced and environmentally friendly supply chains. Embracing green logistics, reducing carbon footprint, and ensuring fair labour practices will become key differentiators in the market.

Adapting to E-Commerce Shifts

The rise of e-commerce has dramatically changed the retail landscape, and its influence on supply chain management is significant. Companies must adapt to the demands of faster, more flexible delivery options, and an increase in direct-to-consumer shipments. This shift requires agile logistics strategies and robust digital infrastructures.

Challenges of Cybersecurity

With increased digitisation comes the challenge of cybersecurity. Protecting sensitive data across a digitally integrated supply chain will be paramount. Companies must invest in advanced security measures and regularly update their protocols to guard against cyber threats.

Staying Ahead of the Curve

To prepare for these future trends and challenges, businesses should invest in ongoing training and development, stay abreast of technological advancements, and foster a culture of innovation. Regularly reviewing and updating digital strategies will be crucial in navigating the evolving landscape of digital supply chain management.